Products

Graphite Electrode

| The graphite electrode is made of high-quality petroleum coke, needle coke, coal pitch and other raw materials through calcination, intermediate crushing, screening, dosing, mixing, compression, roasting, high pressure impregnation, graphitization, machining and other processes, has compact and even structure, good electric conduction and heat-conducting properties, high mechanical strength and strong oxidization corrosion resistance at high temperature, is widely used for arc furnaces and submerged arc furnace to smelt various alloy steel, yellow phosphorus, industry silicon, brown aluminum oxide and other alloy and nonmetal materials. |  |

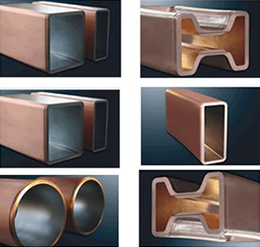

Copper Mould/Spares

| Copper mould is placed in the heart position of continuous casting machine (CCM), its function is to solidify the liquid steel pouring through the Submerged entry nozzle(SEN), guarantees required billet/bloom/slab with enough thick shell to be obtained. Copper mould plays a crucial role in increasing con-casting efficiency as well as improving steel quality. |  |

Calorised Ceramic Coated Lance

|

Calorised Ceramic Coated used a low carbon special thin walled pipe, which is calorized and coated with ceramic materials on both the inner and outer surfaces. In steelmaking, pipes are used for oxygen injection and under this high temperature and severe environment, normal steel pipes that are used as lance will be consumed fast. When using Calorised Ceramic Coated Lance, the consumption rate will improve 6-7 times. |

|

Aluminium Wire

| As Aluminium is a very strong deoxidizer, it is widely use in steelmaking plant in order to achieve the high quality steel grades. Aluminium has a lower density than steel and in the shapes of rode, bar, ingot etc,, Aluminium does not work quite well as an deoxidizer because it floats above the liquid steel and is quickly oxidized. Aluminium in the wire form can overcome this problem as the wire can be forced deeply into the bath. |  |

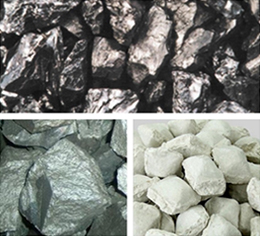

Cinder Ball

| Cinder Ball is a new generation of burnt material for slag making which uses caustic calcined magnesia is compressed into ball form. Slag splashing needs a certain amount of MgO and Cinder Ball is a good replacement of Dolomite as it has a higher MgO content. MgO has a melting point of 2800 degrees Celsius and the MgO content in the slag will improved the viscosity of the slag. Using MgO will also enhance the life span of the refractory lining and help reduce the operational cost. |  |

Light Burnt Dolomite

| Dolomite is a naturally occurring mineral and the chemical composition of this mineral is CaMg(CO3)2. Dolomite can be used in the raw form or after it is calcined to Light Burn or Dead Burnt Dolomite. |  |

Calcium Aluminate

|

Calcium Aluminate is an auxiliary material for steelmaking. It speeds up secondary metallurgy process, especially faster desulphurization. Calcium Aluminate improves overall steel cleanliness. Calcium Aluminate has low melting point and high melting speed. It has no flouride content and does not erode furnace/ladle lining. |

|

Flourspar Lump

|

Flourspar lump is a mineral composed of CaF2. In steelmaking, it is used as flux to reduce the melting point and increase the fluidity of the slag, promoting the absorption of Sulphur and Phosphorous into the slag, thus improving the quality of the steel. |

|

Carbon Additive

|

Carbon Additive includes Calcined Petroleum Coke, Graphitized Petroleum Coke, Calcined Anthracite Coal etc. For steelmaking, the most suitable carbon additive is Calcined Petroleum Coke. Sulphur is a critical element in Calcined Petroleum coke as it impacts the quality of steel. The lower the Sulphur content, the better it is for steelmaking. |

|

Amorphous Graphite

| Amorphous graphite powder is widely used in steel and iron casting as carbon additive to increase the carbon content of steel or iron casting. |  |

Calcined Petroleum Coke

|

Calcined Petroleum Coke is manufactured by calcining raw petroleum coke which is a by-product of the oil refining process. Although it contains slightly higher level of Sulphur and Nitrogen than pitch coke, the price advantage makes it widely used in steelmaking as a form of carbon additive. |

|

Graphitized Petroleum Coke

| Graphitized Petroleum Coke can be used as carbon raiser (Recarburizer) in the production of high quality steel and iron casting. |  |

Calcined Anthracite

| Calcined Anthracite has low Sulphur content and Ash content and is produced when Anthracite is calcined in high temperature. |  |

Ferro Silicon (FeSi)

|

Ferro Silicon is an important alloy in the steelmaking and iron casting process. It is used as a source of silicon to deoxidize steel and helps to prevent loss of carbon from the liquid steel. It is also use as an alloying element to improve the final quality of the steel. |

Ferro Silicon Manganese

|

Ferro Silicon Manganese is mainly used in steelmaking for deoxidation, alloy addition and desulphuriziation in liquid steel. SiMn will react with Sulphur minimizing the formation of iron sulphides which has low melting point. During rolling, iron sulphides will become liquid causing surface cracking. |

Ferro Manganese

|

Ferro Manganese has a manganese content between 65-90%. It is use in the steelmaking process as a deoxidant and alloying addition. It is also use for desulphurization minimizing the formation of iron sulphides which will melt during rolling, causing surface cracks. |

|

Ferro Silicon Inoculant for nodular casting

|

Inoculant promotes graphitization and reduce white cast tendency. It helps to refine the grains, reduces segregation. Use of inoculant helps to improve the mechanical strength and the mechanical properties. It also reduce the internal stress during casting. |

Ceramic Foam Filter

|

Ceramic Foam Filters are used in the filtering of steel, steel alloys and iron casting. It reduces the turbulence during casting and prevents foreign matter from entering the casting. Filters does not chemical reacts with most metals and alloys. |

|

Silicon Carbide

| Silicon Carbide is a cost effective alternative to using ferro silicon and carbon in steelmaking, producing cleaner steel and lower emission as it has lower levels of gas content and trace elements. |

Slag Remover

| Slag Remover has excellent slag binding performance and produces fewer smokes or fumes. A gentle rolling motion is produced when applied during ladle filling and this cleanses the metal by coagulating impurities. It can also form an insulating layer to maintain the metal temperature. |  |