Products

Pure Calcium Cored Wire

Full Name : Calcium

Type of product : pure Ca element

Ca element Melting point (Ca): 839°C (1558°F)

Boiling point (Ca) : 1484°C (2703°F)

Density at 20°C (70°F) : 1.53g/cm

Utilisation:

Pure calcium is mainly used for the treatment of Aluminum killed steel. The low density and the low boiling point of pure Calcium require special addition methods. Cored wire is the most efficient technology to introduce Calcium into liquid steel in order to get high performance/recovery.

The calcium treatment of liquid steel is essential with the objective of combining calcium with alumina and sulfide inclusion in order to control shape, distribution and fluidity of the modified inclusions with following beneficial effects:

- Reduced caster nozzle clogging by alumina (AL2O3 ) inclusions resulting from previous aluminum deoxydation.

- Globularisation of alumina and complex inclusions improve of the transverse properties of the steel: ductility and strength

- Improvement of steel cleanliness.

With its strong affinity for oxygen and sulfur, Calcium has a secondary effect on deoxydation and desulfurization. It forms CaO first, followed by oxysulfides and finally sulfides CaS.

Typical chemical analysis:

Ca:97%-99%

Variations to these main elements and other residuals can be addressed on a case-to-case basis.

Cored wire typical data:

| TYPICAL FILLING RATE | |

| Wire Diameter | 9mm |

| Powder Metric Weight (g/m) | 55 |

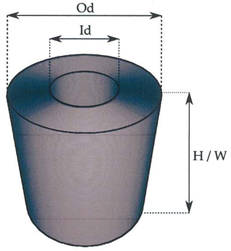

| COIL DIMENSION (mm) | ||

| Type of Coil | Q | J |

| Od: Outside dia. | 1100 | 1100 |

| Id: Inside dia. | 570 | 570 |

| H / W: Height / Width | 700 | 1090 |

| FINISHED PRODUCT (Coil+Cage+Steel Pallet) | ||

| Type of Coil | Q | J |

| Wire length (m) | 6000 | 9450 |

| Powder Weight (kg) | 310 | 480 |

| Gross Weight (kg) | 1460 | 2280 |

Coils can be delivered either horizontal or vertical depending on the design of the injection facility.

They can always be connected for a non-stop injection.

Other types of packaging are available upon request including coil size, pallet type, protective wrapping and reels.