Products

Pure Sulphur Cored Wire

Full Name :Â Sulphur

Type of product : Pure element

Melting point (Ca): 119°C (300°F)

Boiling point (Ca) : 444°C (832°F)

Density at 20°C (68°F): 2.05g/cm3

Utilisation:

Sulphur is often considered a harmful impurity in steel and has to be removed to levels as low as possible.

Despite Sulphur’s harmful effect commonly used to improve machinability of steel by providing optimum chip formation during turing and reduces tool wear.

As the solubility of Sulphur in steel is limited the primary purpose of adding sulphur in liquid steel is to form specific and/or complex inclusions to enchance the machibility of steels.

Sulphur is mainly added in liquid steel as pure element or Sulphur iron/Pyrite mineral.

Cored wire is the preferred addition method due to Sulphur’s low density and low boiling point.

Cored wire methods allows a deeper injection in steel avoiding vaporization of the Sulphur while simultaneously increasing dissolution rate and recovery.

Cored wire improves health and safety issues due to the fact of reducing noxious fume emission.

Typical chemical analysis:

S :Â 99.5 – 100%

Humidity :Â 0.05%max

Variations to these main elements and other residuals can be addressed on a case-to-case basis.

Cored wire typical data:

| TYPICAL FILLING RATE | |||

| Wire Diameter | 9 mm | 13.6 mm | 21 mm |

| Powder Metric Weight (g/m) | 80 | 190 | 430 |

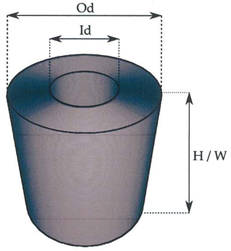

| COIL DIMENSION (mm) | ||||

| Type of Coil | Q | J | W | X |

| Od: Outside dia. | 1100 | 1100 | 1400 | 1400 |

| Id: Inside dia. | 570 | 570 | 800 | 570 |

| H / W: Height / Width | 700 | 1090 | 1090 | 1090 |

| FINISHED PRODUCT (Coil+Cage+Steel Pallet) | ||||||

| Wire Diameter | 9 mm | 13.6 mm | 21 mm | |||

| Type of Coil | QÂ | Â Q | Â J | WÂ | X | W |

| Wire length (m) | 6000 | 2800 | 4400 | 6300Â | 8600 | 2700 |

| Powder Weight (kg) | 480 | 540 | 850 | 1210 | 1650 | 1160 |

| Gross Weight (kg) | 1160 | 990 | 1540 | 2230 | 3010 | 1940 |

Coils can be delivered either horizontal or vertical depending on the design of the injection facility.

They can always be connected for a non-stop injection.

Other types of packaging are available upon request including coil size, pallet type, protective wrapping and reels.