Products

Copper Mould/Spares

Application:

Application:

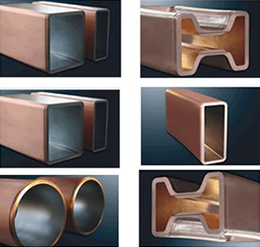

Copper mould is placed in the heart position of continuous casting machine (CCM), its function is to solidify the liquid steel pouring through the Submerged entry nozzle(SEN), guarantees required billet/bloom/slab with enough thick shell to be obtained. Copper mould plays a crucial role in increasing con-casting efficiency as well as improving steel quality. Copper moulds have played an important role in the development of the continuous casting process. Their function is to receive the molten steel and to allow rapid heat transfer from the steel to the cooling water to enable quick solidification. The mould must exhibit excellent thermal conductivity, be resistant for thermal erosion, and be resistant to distortion from thermal stress. So far only copper and a few copper alloys meet the above conditions, both economically and technically.

Size:

| Name | Size(mm) | Arc radius(mm) | Thickness(mm) | Length(mm) |

| Square Copper tube | 70*70~500*500 | 4000-12000 | 6~30 | 800-1000 |

| Rectangular copper tube | (100~500)*650 | 4000-12000 | 6~30 | 800-1000 |

| Round copper tube | Diameter110~1000 | 4000-12000 | 10~30 | 800-1000 |