Products

Aluminium Wire

Description:

Description:

As Aluminium is a very strong deoxidizer, it is widely use in steelmaking plant in order to achieve the high quality steel grades. Aluminium has a lower density than steel and in the shapes of rode, bar, ingot etc,, Aluminium does not work quite well as an deoxidizer because it floats above the liquid steel and is quickly oxidized. Aluminium in the wire form can overcome this problem as the wire can be forced deeply into the bath.

High quality Aluminium wire available in 9mm and 12 mm diameter.

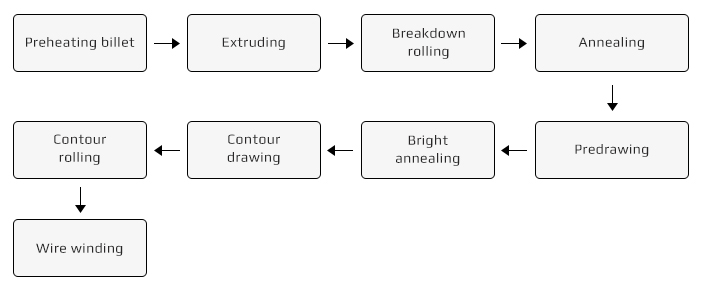

Production process:

Specifications:

|

Constituent |

%Grade |

|

Aluminium (min) |

99.7 |

|

Si (max) |

0.1 |

|

Fe (max) |

0.2 |

Physical Properties

|

Rod Diameter (mm) |

|

9.5 (± 0.5) |

|

Tensile Strength (MPa) |

H-12 Temper H-16 Temper |

83-117 MPa 117-152 MPa |

|

Conductivity (%IACS) |

H-12 Temper H-16 Temper |

61.5 min 61.3 min |

|

Coil Weight (MT) |

|

2.0-3.4 MT |

|

Coil ID (mm) |

|

560 |

|

Coil OD (mm) max |

|

1770 |

|

Height of Coil (mm) |

|

850 |

Application:

Wire aluminium have a widely application in steelmaking industry.

- It is added to furnace, ladle, tundish or ingot mould as a deoxidizer to reach the good quality steel grade or as an additive in refining.

- To treat the soundness of foundries process, a little amount of aluminium about 0.03% – 0.07% is added.

- In nitriding steelmaking, Aluminium is an important alloying agent to combine with Nitride to form an extremely hard case (70 RC).