Products

Cinder Ball

Description:

Description:

Cinder Ball is a new generation of burnt material for slag making which uses caustic calcined magnesia is compressed into ball form. Slag splashing needs a certain amount of MgO and Cinder Ball is a good replacement of Dolomite as it has a higher MgO content. MgO has a melting point of 2800 degrees Celsius and the MgO content in the slag will improved the viscosity of the slag. Using MgO will also enhance the life span of the refractory lining and help reduce the operational cost.

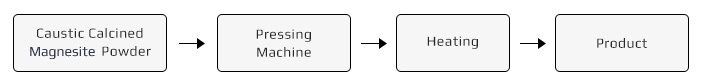

Production Process:

Specifications:

Range of typical values

| Specifications | MgO % | CaO % | C % | SiO2 % | CaF % | LOI % |

| Magnesium | ≤ 70 | ≤ 3 | – | ≤ 13 ≤ 5 |

– | ≤ 22 |

| Magnesium-Carbon | ≥ 60 | – | ≥ 5 | ≤ 4 | – | ≤ 20 |

| Magnesium Calcium | ≥ 50 | ≥ 15 | – | ≤ 3 | – | – |

| Magnesium Flourite | ≤ 40 | ≤ 3 | – | – | ≤ 50 | ≤ 5 |

| Modifier | ≥ 50 | ≥ 10 | ≥ 5 | ≤ 5 | – | – |

Application:

Cinder ball have a very high content of MgO, so it is used to increase the viscosity of the slag (due to the high melting point of MgO at 2800°C). This advantage make the slag to form a protection layer to increase the effectiveness of melting down the scrap, help saving time and energy usage. Moreover, the slag will protect refractory from arc damaging during burning process, as consequences, expanding refractory life time.