Products

Calcium Aluminate

Description:

Description:

Calcium Aluminate is an auxiliary material for steelmaking. It speeds up secondary metallurgy process, especially faster desulphurization. Calcium Aluminate improves overall steel cleanliness.

Calcium Aluminate has low melting point and high melting speed. It has no flouride content and does not erode furnace/ladle lining.

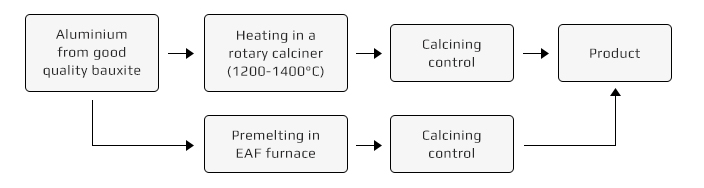

Production Process:

Specifications:

Range of Typical Values

| CaO % | Al2O3 % | SiO2 % max | Fe2O3 % max | MgO % max | F % max | TiO2 % max |

| 30-35 | 50-55 | 7.5 | 2.0 | 3.0 | 0.2 | 2.0 |

| 32-35 | 50-52 | 5.0 | 2.0 | 3.0 | – | 2.0 |

| 32-37 | 42-47 | 6.0 | – | 12 | – | – |

| 45-48 | 35-40 | 5.0 | – | 3.0 | – | – |

| > 45 | 10-20 | – | – | 10-20 | – | – |

| 17 – 20 | > 60 | 5.0 | – | 3.0 | – | – |

Application:

Using Calcium Flouride contains a hidden risk of damaging refractories during steelmaking process due to the potential of forming HF acid, Calcium Aluminate is used as a replacement to protect the refractories as well as the environment.

During Electric Arc Furnace, Calcium aluminate is used to stabilize the composition by absorbing inclusions (Sulphur) in the liquid steel to the formed slag, which help increasing the purity, productivity and quality of steelmaking.

Calcium Aluminate is commonly used in Ladle Furnace and Vacuum Degassing process to help control the Sulphur content to the target requirement of 0.015%.