Raw Materials, Additives & Consumables

Products

Raw Materials, Additives & Consumables

Back

Ferro Manganese

Description:

Description:

Ferro Manganese has a manganese content between 65-90%. It is use in the steelmaking process as a deoxidant and alloying addition. It is also use for desulphurization minimizing the formation of iron sulphides which will melt during rolling, causing surface cracks.

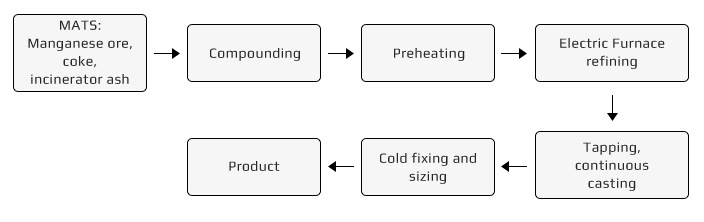

Production process:

Specification:

| Type | Grade | Mn % | C max % | Si % | P % | S max % |

| Low Carbon Ferro Manganese | FeMn88C0.2 | 85.0-92.0 | 0.2 | 1.0-2.0 | 0.10-0.30 | 0.02 |

| FeMn84C0.4 | 80.0-87.0 | 0.4 | 1.0-2.0 | 0.15-0.30 | 0.02 | |

| FeMn84C0.7 | 80.0-87.0 | 0.7 | 1.0-2.0 | 0.20-0.30 | 0.02 | |

| Medium Carbon Ferro Manganese | FeMn82C1.0 | 78.0-85.0 | 1.0 | 1.5-2.5 | 0.20-0.35 | 0.03 |

| FeMn82C1.5 | 78.0-85.0 | 1.5 | 1.5-2.5 | 0.20-0.35 | 0.03 | |

| FeMn78C2.0 | 75.0-82.0 | 2.0 | 1.5-2.5 | 0.20-0.40 | 0.03 | |

| High Carbon Ferro Manganese | FeMn78C8.0 | 70.0-82.0 | 8.0 | 1.5-2.5 | 0.20-0.33 | 0.03 |

| FeMn74C7.5 | 70.0-77.0 | 7.5 | 2.0-3.0 | 0.25-0.38 | 0.03 | |

| FeMn68C7.0 | 65.0-72.0 | 7.0 | 2.5-4.5 | 0.25-0.40 | 0.03 |

Application:

- In steelmaking, Ferrous Manganese is considered as a crucial factor to improve the quality of steel. It plays a key role as a deoxidizer and sulfur balancing material. As a low cost and outstanding technical benefit, nearly 90% of this element added to steel industry so far.

- In Aluminium alloy, Ferrous Manganese is taking advantage in improving corrosion resistance.

- This powerful material also added into copper alloy with a little amount (0.1-0.3%) to generate deoxidization process, which help enhance the physical strength of the alloy.

- Some applications of Ferrous Manganese can be used in battery industry.